Capabilities

Diversified Pattern and Engineering is leading the foundry industry in the production of quality Molds, Patterns, and Fixtures.

We have served a wide variety of customers with different tooling needs. Every job starts with

our commitment to having our engineering team work closely with customers to get the right

design in quickly.

Diversified Pattern and Engineering is also an industry leader in the design and manufacture of

leak decay fixtures, saw fixtures, and trim dies.

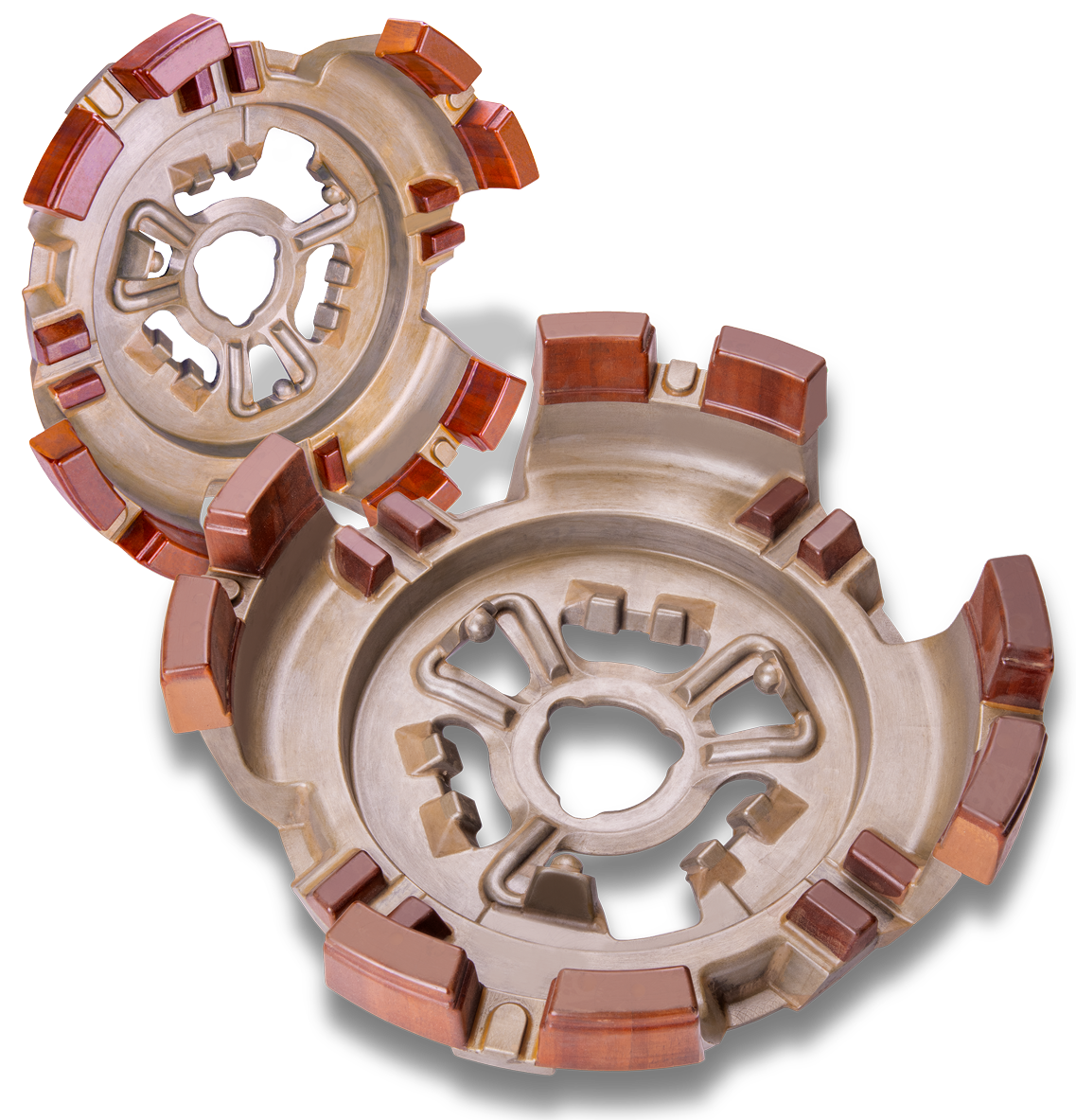

Permanent Molds

Permanent mold casting generally uses a clamped, two-part, reusable mold. This mold is usually cut from cast iron or steel (historically, stone or fired clay) to cast low to moderate-melting-point metals.

This process produces castings with much higher surface finish, dimensional

accuracy, and mechanical properties than sand casting.

DISA Molds

Utilizing both vertical and horizontal molding methods, DISA enables manufacturers to produce high-quality castings efficiently and cost-effectively. Our expert mold makers are dedicated to manufacturing precision molds that meet your exact specifications.

From concept to production, we work closely with our customers to ensure every detail is accurate and exact.

Whether you need a prototype mold, production mold, or fixturing, we have the skills and expertise to get the job done right.

Hunter Molds

Diversified Pattern and Engineering supports Hunter as a premier developer of advanced match plate molds and mold-handling solutions for the foundry industry.

This includes processes such as composite, centrifugal, continuous, full mold, gravity, die casting, deep cavity molds, and a variety of other mold types.

Electrical Discharge Machining (EDM)

Diversified Pattern and Engineering employs the Chmer HM 65GT CNC mill to machine the complex graphite electrodes used in our Chmer CM1065c EDM Die Sinker. Electrical Discharge Machining, or EDM, uses electrical discharge from a graphite or copper electrode to erode the workpiece. The Z-axis is retracted repeatedly during machining to clear debris. Our EDM is widely employed in the pattern-making process.

It machines long reach and finely detailed cavity features in the pattern without imposing any machining or impact stress on the workpiece. It also reduces the need to post-process the surface for quality improvement or hardening.

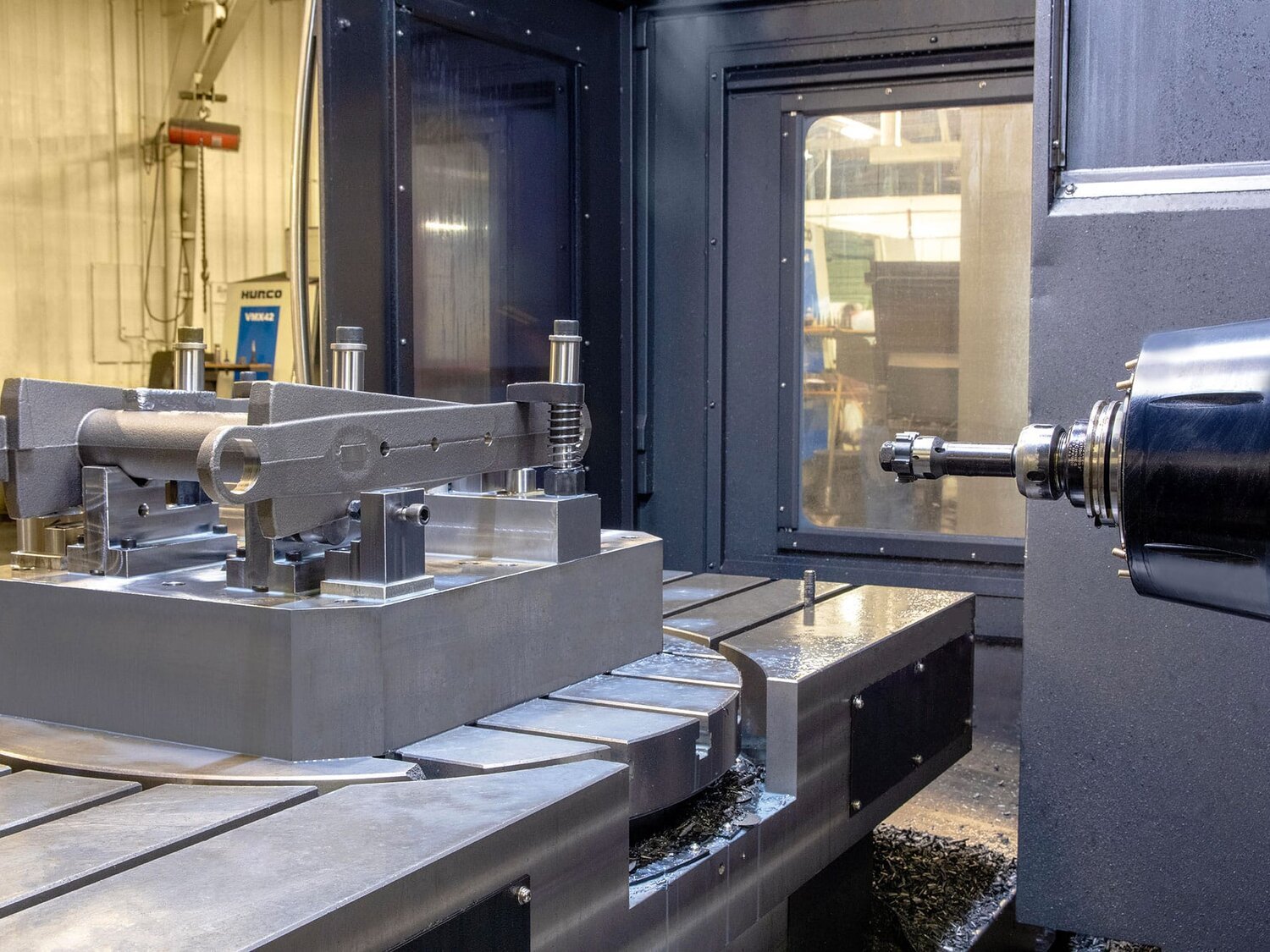

Machine Casting Fixtures

Let Diversified Pattern and Engineering design and build your casting machine fixtures. Whether it be for prototyping or production, our casting knowledge makes us the perfect fit to produce your machine fixtures.

Things to consider when designing machining fixtures:

- Prototype or Production volumes.

- Manual or pneumatic clamping.

- Casting locators and datums.

- Casting machining specifications.

- Vertical or horizontal machine.

Our knowledgeable team will work with you to design and build a fixture suitable for your needs.

Saw Fixtures

Diversified Pattern and Engineering designs and builds custom CNC machining and targeting fixtures that meet the highest aerospace standards. We also produce assembly, glue, and check fixtures for the most difficult-to-engineer and manufacture core packages.

We produce the following fixtures for a variety of complex engineered applications:

- CNC target fixtures

- Machine fixtures

- Core assembly/glue fixtures

- Assembly check fixtures

- Casting check fixtures

- Saw fixtures that make cutting gating off much more productive and much safer

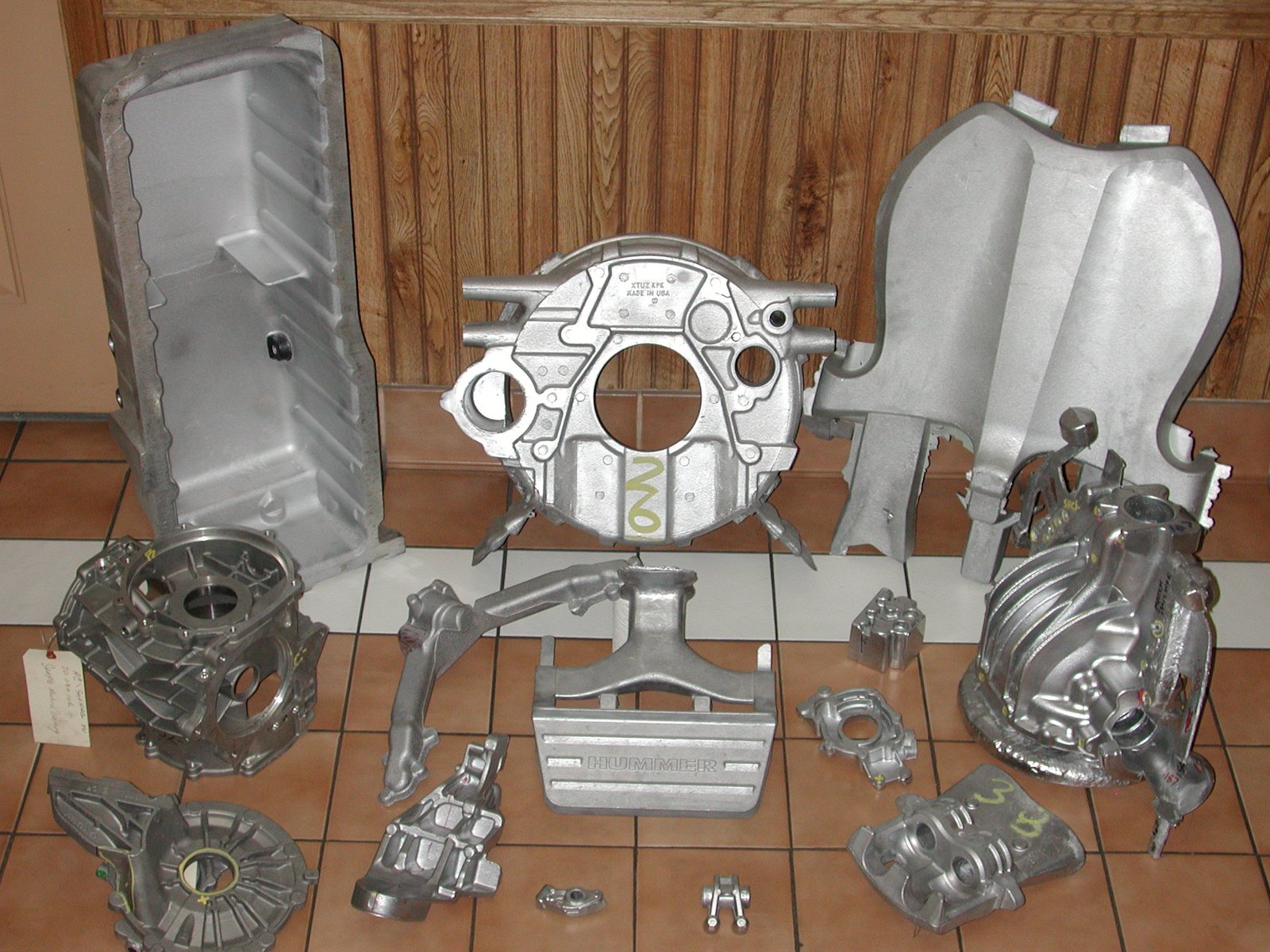

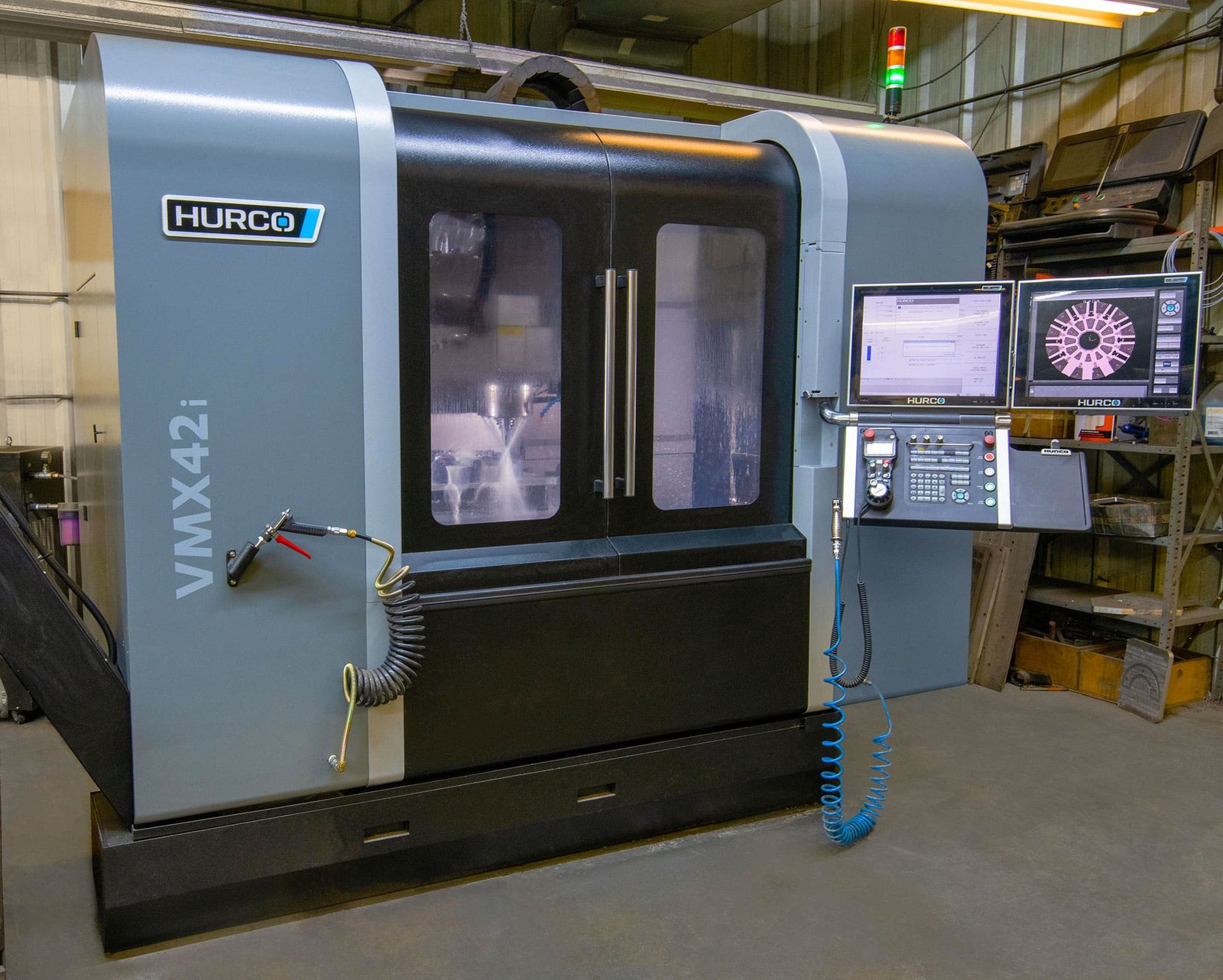

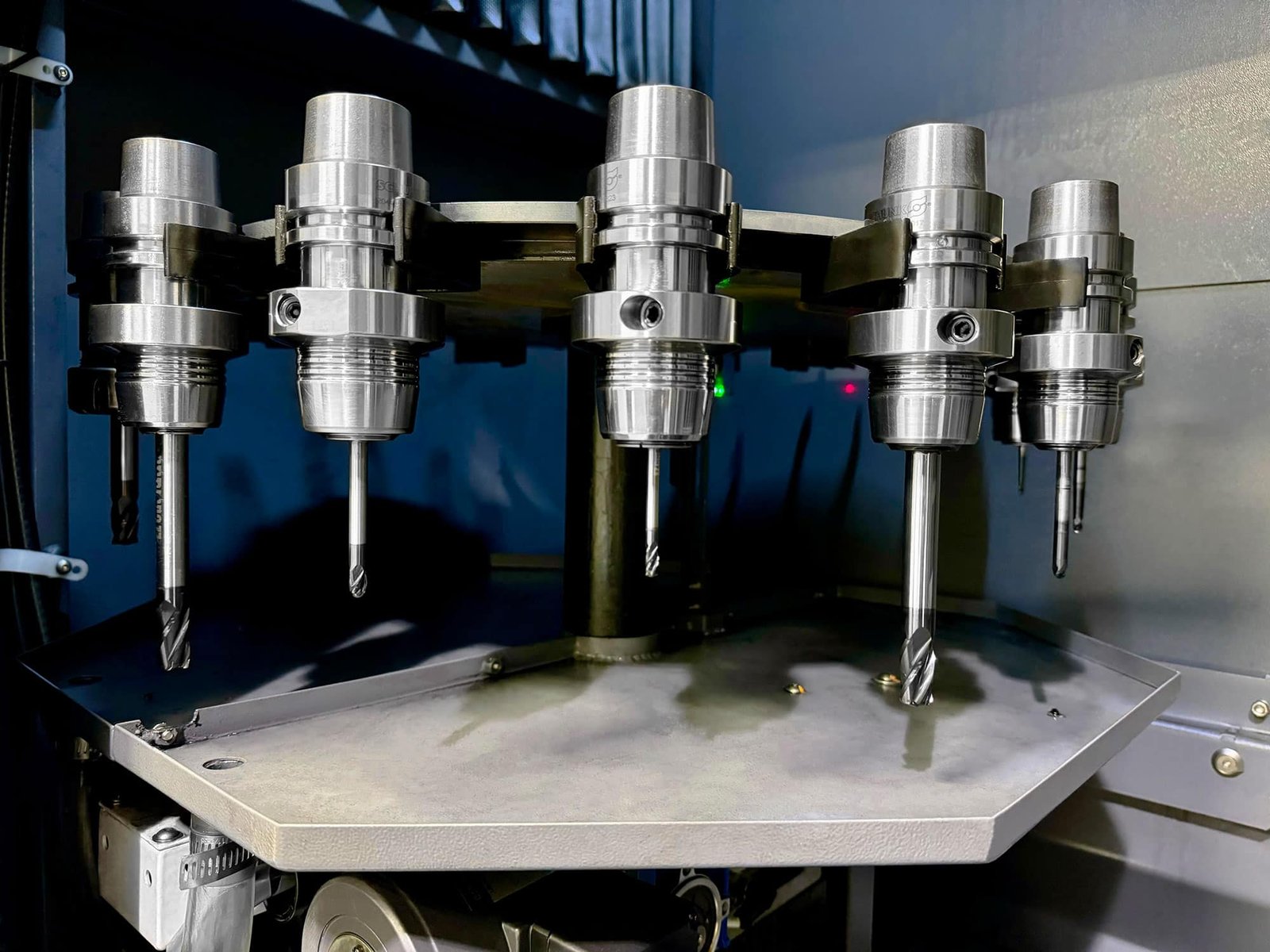

Machining Casting and Patterns

We use Solid Edge 3D modeling software and Work NC to generate a CNC toolpath to quickly and efficiently transfer your designs to our Hurco machining centers, saving you valuable time and money.

Patterns are our namesake at Diversified Pattern and Engineering. But did you know we can also machine your finished aluminum and iron castings? Let us be your prototype or low-run casting machining source. Our experienced team is ready to take on your project, from design concepts to finished goods. Let us be your one-stop source for tooling and machining.

Wood Patterns

Wood is the basis of most sand-casting patterns, usually from a hardwood that can withstand the heat and humidity of the foundry. These can be used for hundreds of castings but will eventually begin to lose pattern conformity or split. However, they’re relatively inexpensive to make and can create very large castings. Diversified Pattern has a well-equipped wood pattern shop.

Customers know they can count on Diversified Pattern and Engineering for a superior

product when it comes to wood patterns.

Eiusmod tempor

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

Incididunt ut

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

Magna aliqua

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

Minim veniam

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

Diversified Pattern is also a industry leader in the design / manufacturing of leak decay fixtures, saw fixtures, and trim dies.

Contact

Have a project? Request a Quote

Upload a CAD file now for a quote. We offer custom cutting of large projects or prototypes—fast, neat, and cost-effective. Contact us today for a free quote on your next project.